Bridge inspection vehicle is a special vehicle that provides a platform for bridge inspectors. It is equipped with a bridge detector, and is used for flow detection and bridge maintenance. The truss bridge inspection vehicle has a complicated structure and is costly, but it works stably with a wide detection range, strong carrying capacity, and high operating efficiency.

The technology of truss bridge inspection vehicle has become mature internationally now. For instance, the bridge inspection vehicles from Capgemini, Breining and Morgan with a high level of technology and reliability, a unified product structure, and a modular design have great advantages in technical performance and reliability.

The truss-type bridge inspection vehicle with a long working platform mostly adopts the 2 sections, 3 sections, or multiple sections of telescopic booms. The telescopic arms are connected via a slide way or a slide bar. The truss bridge inspection vehicle working platform is mainly welded with square tube materials of different cross sections, and the slide way part is generally U-shaped. Therefore, when establishing the finite element mode, the beam unit is mainly used, and the reinforcing plate at the end of the working platform adopts the shell unit. Through finite element analysis, corresponding data such as the displacement change of the working platform under various working conditions, comprehensive stress analysis, bending stress distribution, and axial application.

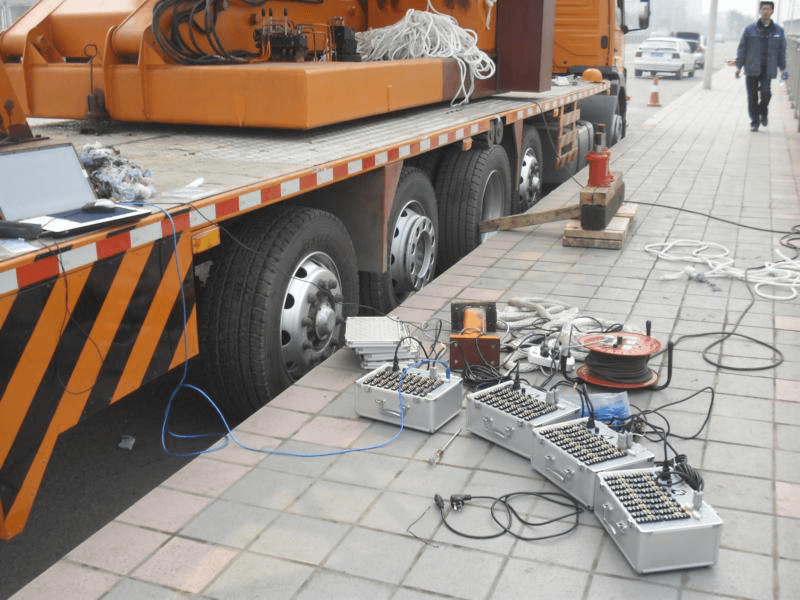

When performing static stress test on the work platform, Dynatronic load it with weights according to different working conditions, and start recording test data after the work platform is stationary. According to the results of finite element analysis and traditional theoretical calculation data, the testers determine the distribution position of the stress test points on the work platform, and arrange as many strain and stress test points as possible.

At present, various types of bridge-building machines designed and produced in China have shown the features of convenient, stable, safe and fast, high-quality, and good economic performance during construction. The performance indicators are able to meet the relevant national regulations and bridge construction of railway passenger lines Claim. With the continuous application and improvement of domestic bridge-building machines, the machines will fully meet the needs of high-speed railway and highway bridge construction in the future.