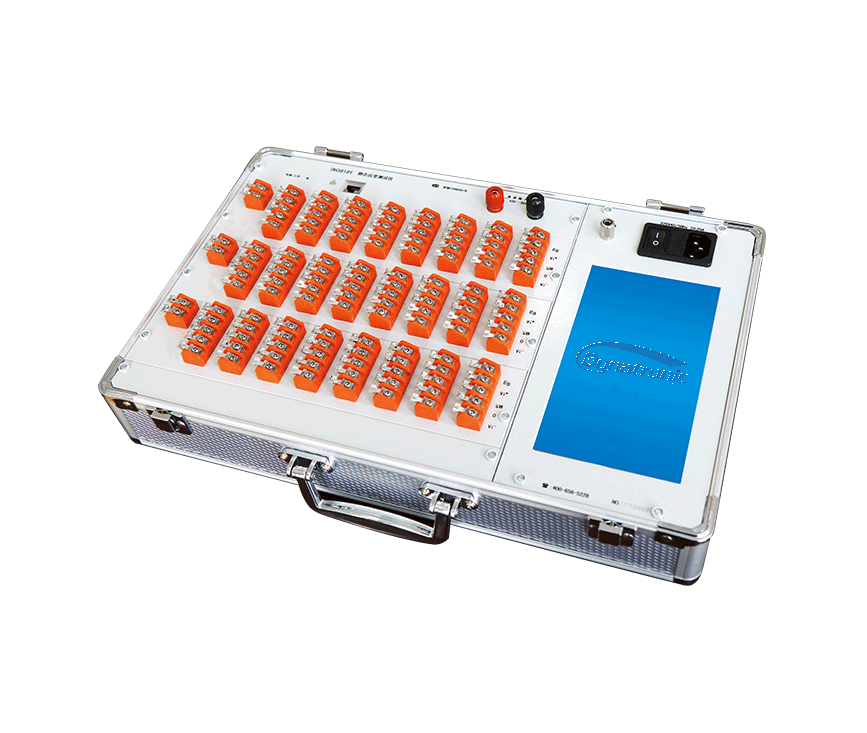

SE-884U Static Stress-strain Testing and Analysis System is a LCD static strain tester specially designed for laboratory. Each hardware includes 8, 16 or 24 measurement channels. Each measuring channel can measure force, displacement or strain. When measuring, the functions of sampling control and data analysis are realized by LCD or computer. The system can be widely used in the static structural performance test of universities, industrial research institutes, engineering testing sites and product development process.

It can realize multi-channel parallel acquisition and high-speed and long-time continuous sampling.

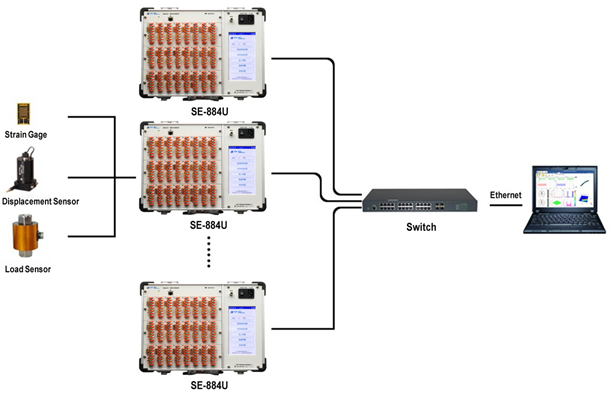

One computer can control multiple acquisition instruments for sampling, which can meet the needs of multi-channel and high-precision measurement.

The computer communicates with the instrument through Ethernet, carries out parameter setting (range, sensor sensitivity, etc.), clearing, sampling, stopping and other operations of the collector, and transmits the sampling data in real time.

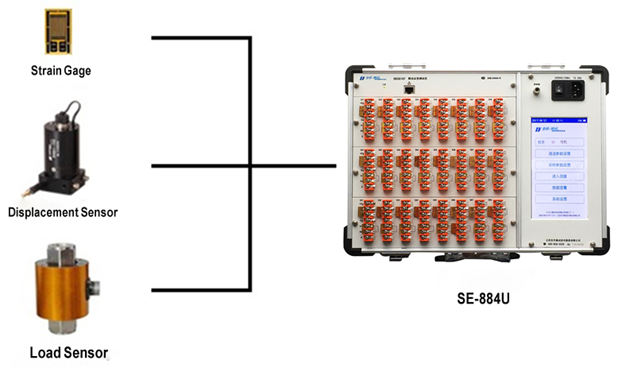

It can cooperate with various bridge sensors to accurately test the force, pressure, displacement and other physical quantities.

Any measuring point can be set as compensation measuring point, or common compensation terminal can be used for compensation.

According to the output sensitivity of the sensor, the unit dimension of the measured physical quantity is normalized and displayed directly.

According to the output sensitivity of the sensor, the unit dimension of the measured physical quantity is normalized and displayed directly.

DC power supply can be used, and lithium battery power supply module can also be selected.

LCD control function, screen size is 7.0 inches.

| Number of Input Channel | 8channels/16 channels/24channels(Three Types) |

| Full-scale Voltage Value | ±30mV, 0 ~ 2V switching |

| Strain Measurement | |

| Full-scale Strain Value | ±30000με |

| Min. Resolution | 0.1με |

| Indication error | ≤0.5%±3με |

| Noise | ≤0.5μεRMS |

| Zero Drift | ≤2με/4h |

| Self-Balancing Range | ±20000με (±2% of strain gauge resistance) |

Strain Gauge Sensitivity Coefficient | 1.0 ~ 3.0 (Auto. calibrating) |

| Bridge Excitation | |

| Bridge Configuration | Full, half, three-wire quarter bridge, public compensation quarter bridge |

| Bridge Completion Resistors | 120Ω, 350Ω (Three-wire quarter bridge) 60Ω ~ 20000Ω (Half bridge / Full bridge) |

| Bridge Voltage | 2V, 5V, 10V DC |

| Output voltage range (DC) | 2V |

| Accuracy | ≤0.1% |

| Stability | ≤0.05% per hour. |

| Maximum output current | 30mA per channel. |

| Resistance correction range | 0~100Ω |

| Communication | Gigabit Ethernet |

| Working Mode | |

| Offline work | touch screen operation, data storage to the chassis, and support data recovery |

| Online work | realize communication and data transmission with calculation through Ethernet |

| A/D Converter | 24 bits |

| Sampling Rate | 1Hz, 2Hz, 5Hz, 10Hz, 20Hz, 50Hz, 100Hz, 200Hz per channel |

| Static Sampling | 1Hz, 2Hz, 5Hz per channel |

| Dynamic Sampling | 10Hz, 20Hz, 50Hz, 100Hz, 200Hz per 4 channels(each module) |

| Power Supply | |

| AC power input | 220 V (± 10%) 50 Hz (± 2%) |

| DC power input | 10 ~ 36 VDC |

| Vehicle 12 VDC | |

| Dimensions | 395×275×107mm |

| Weight | Approx. 4.5kg |

| Environmental Conditions | |

| Operating Temperature | 0°C to 40°C |

| Operating Humidity | 20 ~ 90%RH@40°C |

| Storage Temperature | - 40°C to 60°C |

| Storage Humidity | 90%RH24h@50°C |

| Vibration | Frequency cycle range: 5Hz ~ 55Hz ~ 5Hz Drive amplitude (peak): 0.19mm Sweep frequency: ≤1Oct./min Duration of resonant: 10min |

Figure 1 Single System Block Diagram (With Sensor)

Figure 2 Single System Block Diagram

Figure 3 Multiple System Block Diagram

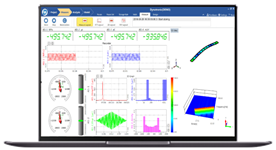

DE-BPS Basic Platform Software

Running on XP/Win7/Win8/Win10 operating system

Parameters setting, Function control, Real-time/post-acquisition analysis, data browsing, cursor readouts, scaling curve, data management and simple processing, report generation, long-term continuous data recording, etc.

| SE-844U Battery module(Optional) | |

| |